Kaplan Homes Display Centre @ Smeaton Grange, NSW, Australia

The end result: see how an ENTTEC LED pixel system is used to great effect in the Kaplan showroom.

In mid-2021, ENTTEC received a query from Anthony Cairns from Kaplan Homes, an innovative high performance Sydney builder providing luxury and lifestyle living. The brief was to bring something exciting, visual, and unique to their new display centre that would be like no other, featuring two full size display homes inside.

Prior to his new role within Kaplan Homes, Anthony spent 17 years in the live music entertainment industry, having worked and travelled extensively with A-list bands worldwide, including 10 years with Kings of Leon as their visual director, living out of Nashville, Tennessee.

With so long spent designing, programming and operating live concerts using LED, projection and camera systems, he was keen to permanently install pixel-mapped features to his new project to create a grand lobby experience, and came prepared with scopes, designs, drawings and annotated photos.

In the past, Anthony had used many high-end LED setups such as Barco, Roe, Winvision, Nocturne, PRG, Lighthouse and other touring systems, but this time sought out the services of ENTTEC to maintain a high standard in the systems he was aiming to commission.

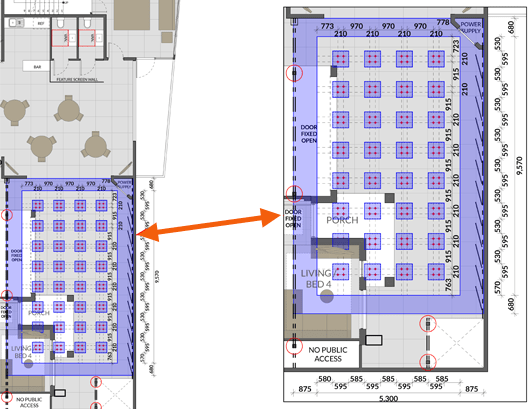

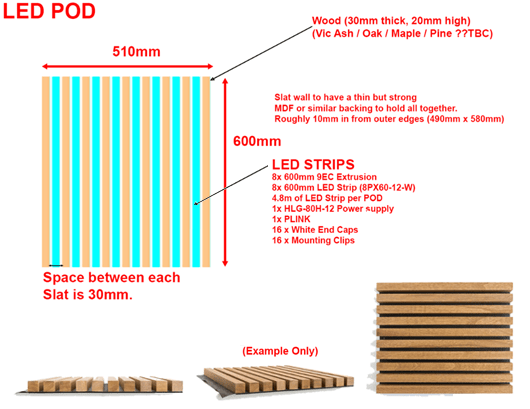

The general concept was to install vertical LED lines on wall segments, plus an array of 600mm square pods in the ceiling. With assistance from the ENTTEC sales team, this was quickly translated into a workable design featuring repeating pods.

Anthony’s concept designs proved invaluable in helping to identify the optimum solution to turn his ideas into reality.

As with most projects, this one involved a consultative approach and lots of back and forth to:

• Learn and understand the systems involved.

• Work with physical samples to get practical experience.

• Value engineer the quoted options to land on a system that would meet aesthetic requirements while also conforming to budgets.

ENTTEC were able to use this information to provide an end-to-end solution. Working with the drawings, the team was able to draw up a control layout.

Ingredients:

- ENTTEC LED Mapper (ELM) award-winning LED pixel mapping software.

- ENTTEC PIXELATOR 48-Universe Ethernet to pixel protocol converter.

- ENTTEC PIXELATOR MINI 16-Universe Ethernet to pixel protocol converter.

- ENTTEC PLink Injector (12-24V) – Engineered to extend your LED pixel layout over long distances.

- ENTTEC 12V RGB pixel strip (8PX60-12-W). Bright and efficient, with 60 LEDs per metre.

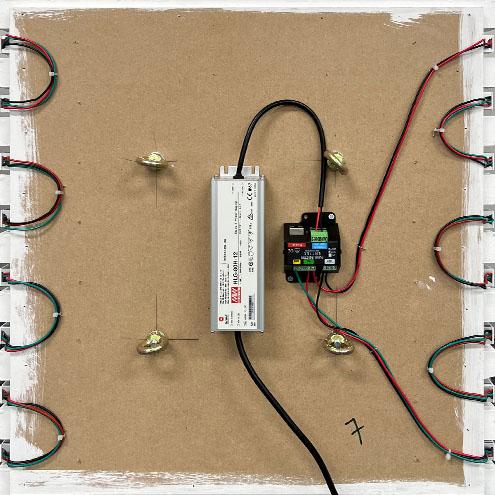

During the value engineering process, it was decided to remove the wall lines, in favour of cove lighting, so that those savings could be diverted towards having a higher resolution pixel strip in the ceiling pods. Also, going with 12V for the pixel strip ensured that each pod would be a self-contained unit with a simple layout and straightforward wiring. Anthony’s goal was not only to achieve something special aesthetically and visually, but also practical in longevity and serviceability.

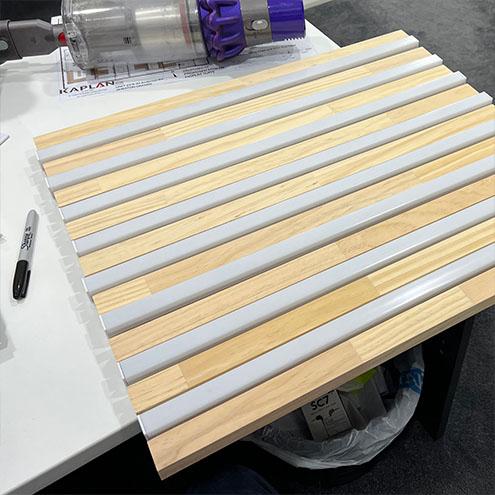

With ENTTEC’s experience in making bespoke LED and pixel bars, we were able to advise on notching out the provided extrusion to allow for ease of assembly with rear-entry cabling. Anthony did a great job of making the LED pods – four large eye bolts on the rear provided stable mounting points for each panel.

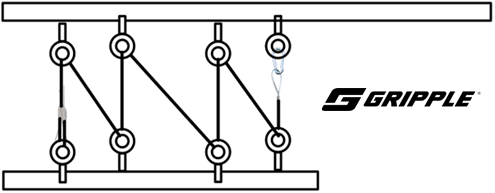

Using fixed ceiling hooks, however, could make levelling the panel rather awkward if it was going to be secured using four independent chains and karabiners. ENTTEC’s sales team was able to circumvent this potential issue by recommending and sourcing Gripple hangers with 3m of cabling.

This way, the pods could be mounted easily with the hanger looped through each eyelet like a pulley system, with the need for only one cable to be tensioned to raise or lower the entire panel.

Anthony’s workmanship with the pixel bars was exemplary for someone so relatively new to pixel lighting. With guidance from ENTTEC’s LED tips & tricks series, as well as seeking advice from the sales team and diligent experimentation, he found the most suitable wire gauge for the wire connections, soldering temperature, and even heat shrunk individual cores to provide additional protection from short circuiting.

Dabs of epoxy along the base of the strip, in addition to the adhesive backing make for a secure connection that will last thousands of hours of thermal cycling.

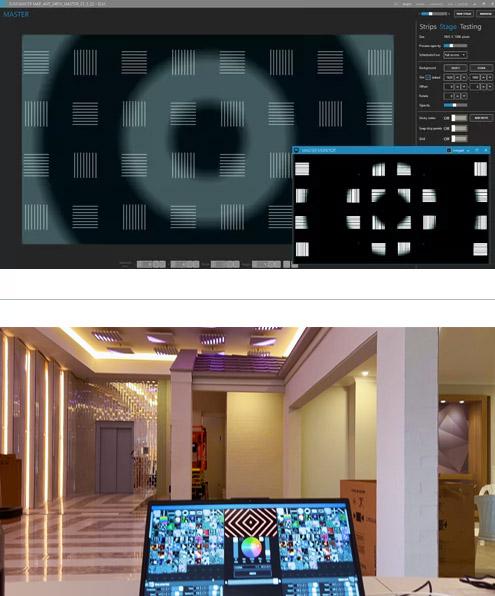

It was around this time that Anthony engaged the ENTTEC team for a training session on our award-winning LED mapping software package, ELM.

Our mission was to map out the pixel pods, and during the one-hour session we were able to get to a point of mapping out enough pods to replicate and cover the rest of the ceiling that was being constructed.

The training provided allowed Anthony to complete the project file 1:1 with the physical installation to truly map and represent the final project.

What a result!

In any given project, however, not everything is guaranteed to run like clockwork.

The project faced challenges especially when burn-in tests were done prior to the pods being mounted. Anthony was insistent in soaking these pods with dynamic colour shows to make sure they were performing 100% before being installing in the ceilings

Most of the pods appeared to run fine but a fraction exhibited a strange phenomenon whereby the pixels at the ends of the string were showing different colours alongside some instances of flickering.

While not ideal, integration issues like this can happen with any project – fortunately Anthony was able to work with the ENTTEC team to isolate variables and trouble shoot the system.

• By checking the ELM file, it was clear that show programming was not at fault.

• Checking network traffic on the pixel controllers confirmed that Art-Net was coming through stably.

• Replacing sections of pixel strip seemed to resolve the issue and when ENTTEC picked up a sample pod to test out, the team was able to scope the data streams and determine that the some of the chips were showing inconsistency in the data transmission.

This was resolved by providing replacement strips and the system now runs stably.

The end result

The completed installation featured painted wooden battens sandwiching the LED extrusion – this was a great choice by Anthony to build a resulting pod that could better blend in with the painted ceiling and really show off the high-res pixel display to maximum effect.

This approach ultimately gave us more pixels and surface area with which to display visuals, but also provided a ceiling design with character in its own right, even if the LEDs were switched off.

Combining 32 of these pods together to create a large array further leverages the control system, and the high-resolution strip allows Kaplan to get the most out of their chosen pixel patterns.

Opting for simple cove lighting around the periphery gives the space an elegance and wow-factor, and because the pixels are fully controllable, the system can transition from subtle sophistication to loud and vivid.

And when we say loud, we mean it literally: the showroom facility features an integrated audio system. Another great advantage of using ELM software is that it enables the pixel feature to sync seamlessly to the music with audio-reactive patterns providing a fully immersive experience for the visitor.